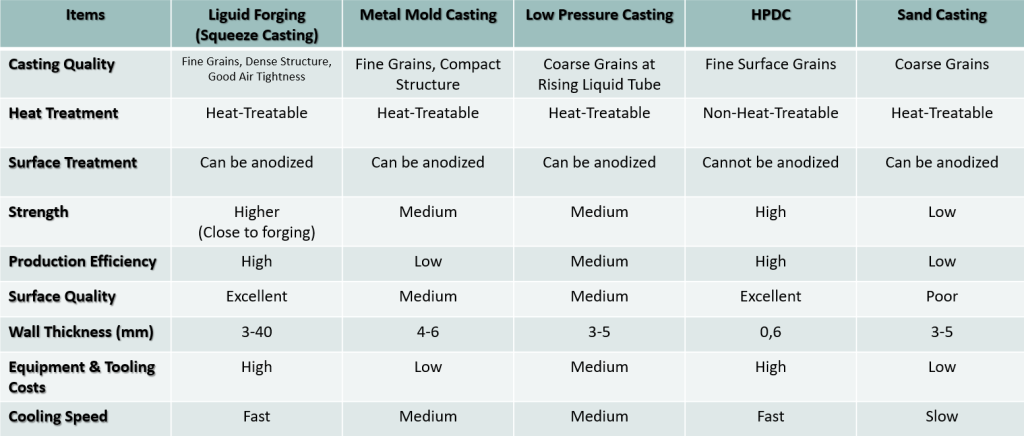

Advantages Of Squeeze Casting

Tensile Strength

Suitable for the production of high‐strength, high‐toughness safety parts and structural parts

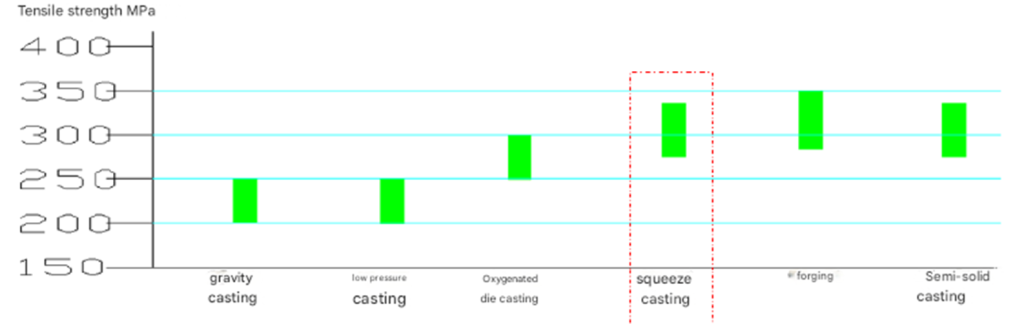

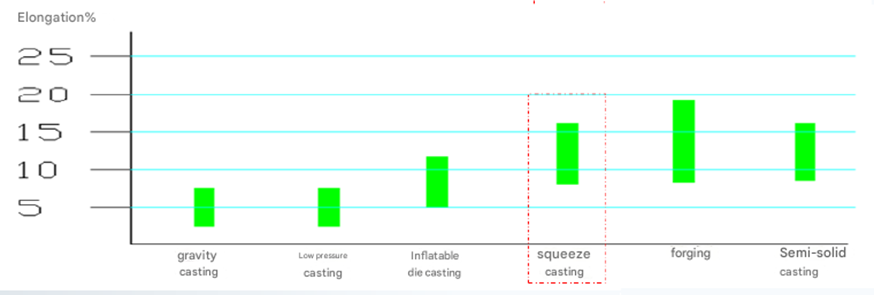

Elongation

Under the premise of ensuring performance, the weight is reduced by about 10%, and the elongation is 2‐3 times that of conventional LPC

| Parts | Tensile Strength Mpa | Elongation % | Hardness HB |

| 16’’ Aluminium Wheel (Rim) | 295 | 10 | 89 |

| Chassis Bracket (TESLA MODEL 3 / Y) | After T6 heat treatment, the tensile strength ≥315Mpa, the elongation ≥8%, the runner can be automatically cut off during the casting process | ||

| Control Arm (Ford) | After T6 heat treatment, tensile strength ≥300Mpa, elongation ≥8% | ||

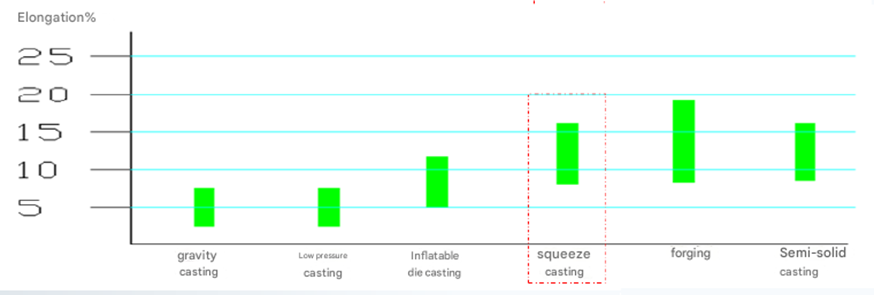

Good Airtightness

Suitable to produce high air tightness parts (air pressure and oil pressure resistance), such as pump bodies and shells

Weldable

Suitable for Welding process

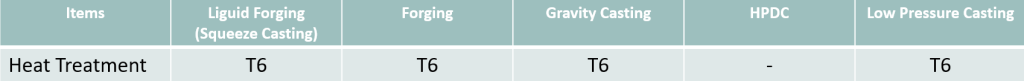

Heat Threatment

Higher mechanical strengths by applying heat treatment (T5 – T6)

High degree of Automation

The squeeze casting production line can realize full automation of the processes of liquid feeding, spraying, picking, punch lubrication, proportioning, integrity testing, cooling, gate removal, burr cleaning, marking, and conveying.

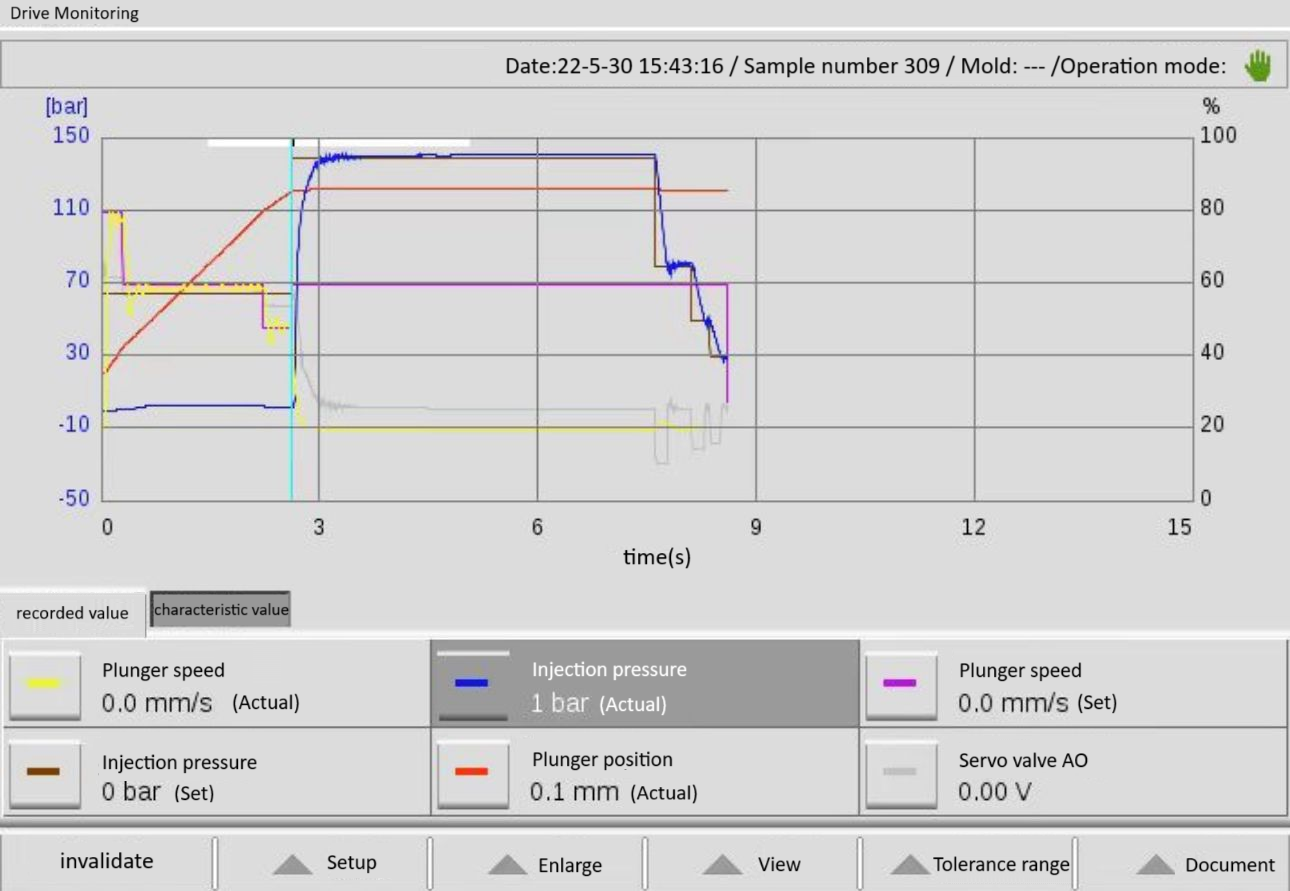

High degree of Automation

The squeeze casting process can realize intelligent management, real‐time monitoring and adjustment of key process parameters such as injection speed, pressure etc., and finally adaptive and stablizing the adjustment of process parameters.

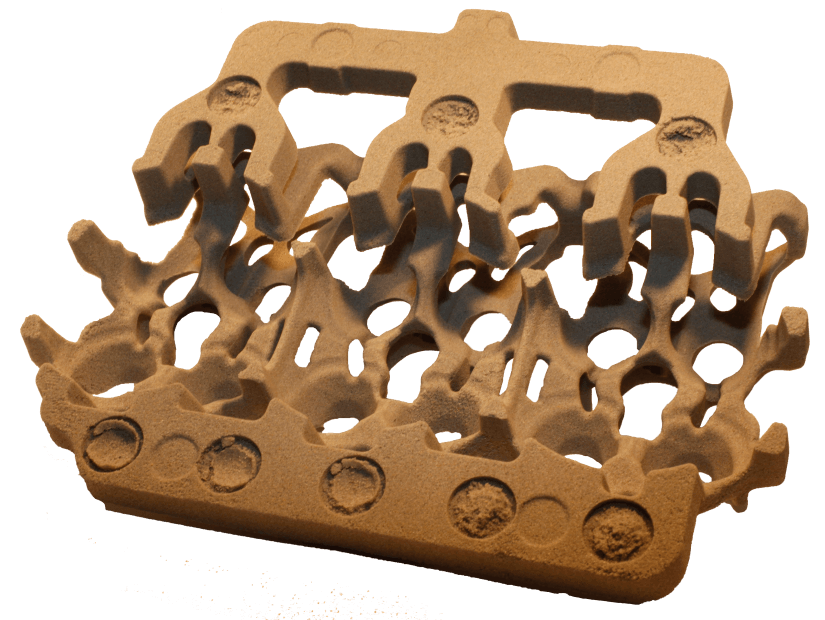

The sand core process can be used

•Significantly reduce aluminum alloy material, mold cost and machining cost. With using sand cores, liquid die forging no longer needs to produce complex hollow parts through the method of “filling the inside and then machining out”, thus saving aluminum alloy.

•Special sand core liquid forging production internal support body mold, used to produce complex structures, hollow parts, with high pressure resistance, easy to collapse characteristics, that is, can maintain the shape of aluminum liquid during the production pressurization process, and can collapse after the production.

•Tooling costs are reduced by 40%.

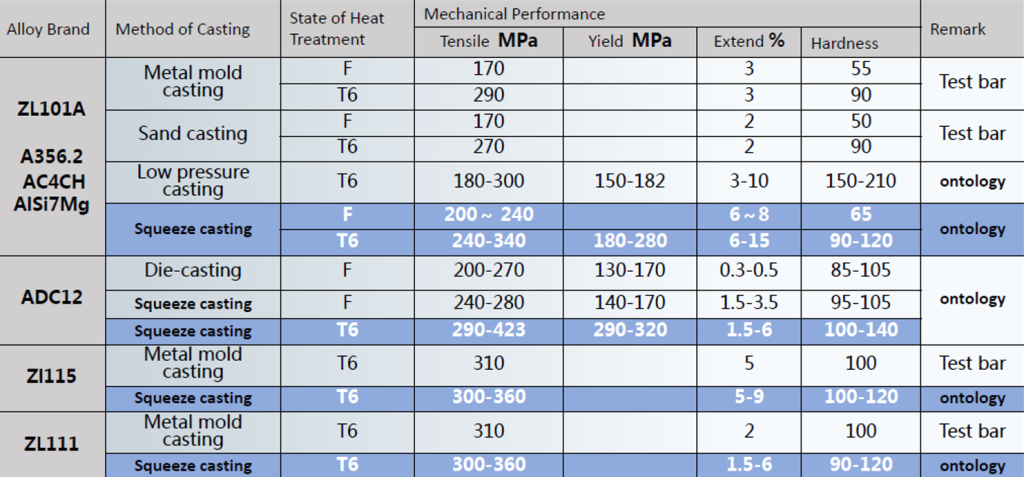

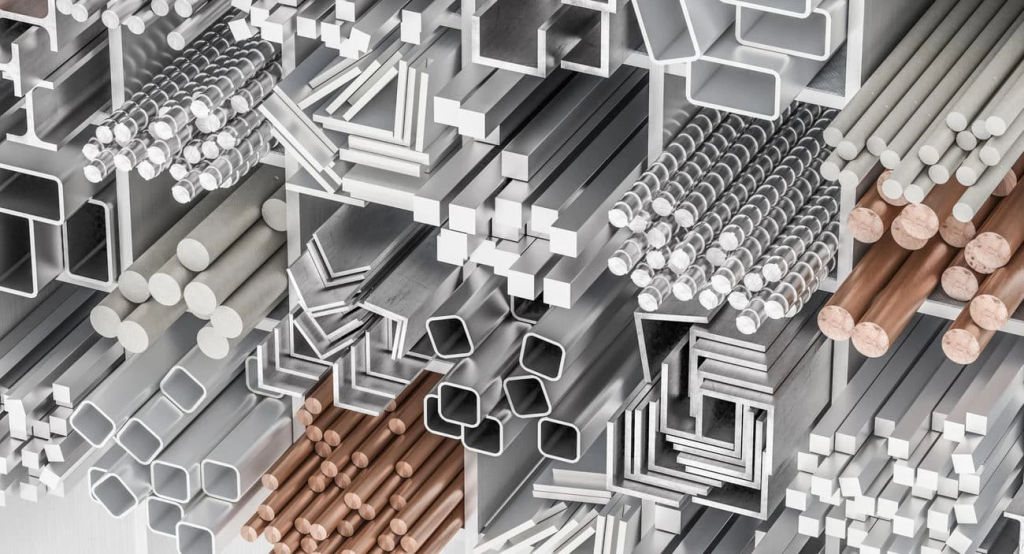

Wide range of applicable alloy materials

•Suitable for a variety of alloy materials: cast aluminum, magnesium alloy, wrought alloy, composite materials, as well as copper, zinc alloy, gray iron and ductile iron, etc.

•Conventional cast aluminum alloy: ADC12\A 356\A 357\A319 \AlSi9Mg……..

•Composite materials (Obvious Advantages)

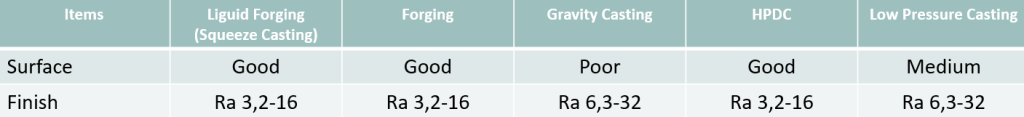

Good appearance quality and High dimensional accuracy

Less or no processing, reducing the margin conducive to surface treatment

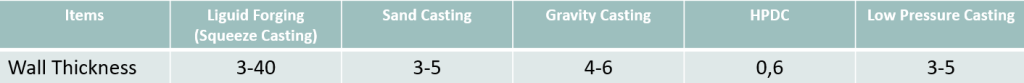

Wide range of wall thickness

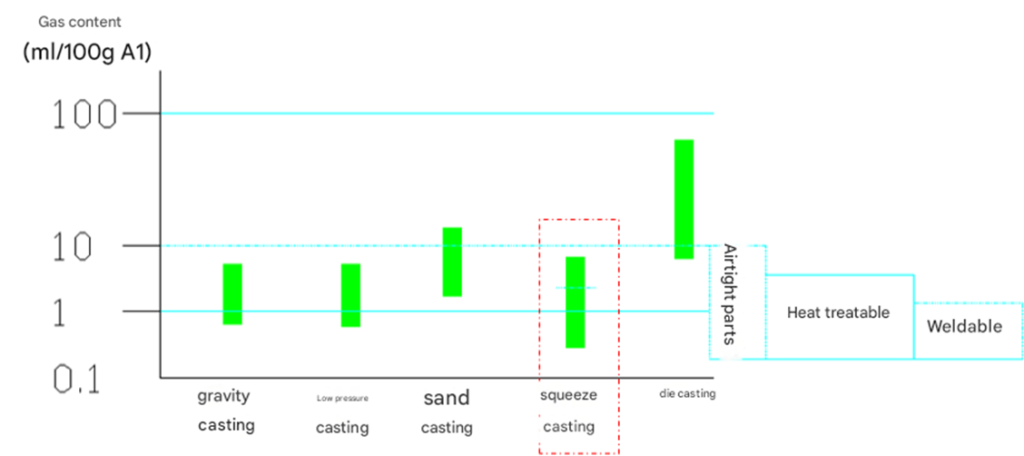

Comparison Table